ANNUAL REPORT 2018

American Coatings Association Scroll down to read more or click here to download the full report2018 Annual Report

American Coatings Association Scroll down to read more or click here to download the full reportMESSAGE FROM THE PRESIDENT

I am very proud to say that 2018 was another successful year for ACA. I’d like to take the opportunity to highlight many of the association’s activities and successes of the past year in this 2018 Annual Report.

The report focuses on four areas in which ACA engaged on behalf of the industry:

• Regulatory Reform

• Science & Technology

• PaintCare®

• Sustainability

The Annual Report also includes a listing of ACA’s 2018 Accomplishments, showcasing the breadth and achievements of ACA’s engagement.

In the year ahead, we will continue to ensure the welfare and advancement of industry. Undoubtedly, 2019 will bring additional challenges and opportunities; your support and that of your fellow members makes it possible for ACA to meet them, and we thank you.

![]()

REGULATORY REFORM

Efforts at EPA

In 2018, ACA pressed for regulatory reform at the U.S. Environmental Protection Agency (EPA). ACA’s advocacy centered on EPA reconsideration or repeal of burdensome and counterintuitive environmental regulations that particularly yoke the paint and coatings industry. ACA seized the opportunity provided by two Executive Orders seeking reform of onerous and costly regulatory policies, becoming a champion for revocation of agency’s eponymous “Once-in, Always-in” policy.

The “Once-in, Always-in” policy was a May 16, 1995 EPA memorandum titled, “Potential to Emit (PTE) for Maximum Achievable Control Technology (MACT) Standards – Guidance on Timing Issues,” from the director of U.S. EPA’s Office of Air Quality Planning and Standards to Regional Air Division directors, commonly known as the “Once-in, Always-in” policy. EPA had applied this policy for some 13 years as a ‘rule,’ with binding effects on the regulated community, including very burdensome compliance costs.

Under the “Once-in, Always-in” policy, a facility defined as a ‘major source’ could become an ‘area source’ (i.e., minor source) by limiting its PTE Hazardous Air Pollutants (HAP) below the major source thresholds by Dec. 11, 2005 — the last compliance deadline listed under the MACT standard (also referred to as National Emission Standards for Hazardous Air Pollutants). However, a source that failed to achieve “area source status” by Dec. 11, 2005 would remain subject to the standard, even if it subsequently

reduced HAP emissions below major source levels at a later date. Simply put, sources would always be subject to the MACT rules, regardless of whether the source was no longer a major source of HAP — once-in, always-in.

Adding to its irrationality, the “rule” had heavy compliance costs attached. This policy compelled facilities to install costly add-on control equipment. These thermal oxidation units require a significant capital investment — millions of dollars per facility — and annual operation and maintenance costs: several hundred thousand dollars per facility per year in fuel cost alone.

EPA Estimates Related to Coatings

Industry MACT Rule Compliance:

OVERALL ENERGY DEMAND INCREASE

5.83 TRILLION BTUs

TOTAL CAPITAL EXPENDITURE

$184 MILLION

YEARLY OPERATING COSTS OF NEARLY

$91 MILLION

INCREASE IN CARBON DIOXIDE, NITROGEN OXIDES

AND CARBON MONOXIDE EMISSIONS

987 TONS PER YEAR

REGULATORY REFORM

For years, ACA urged and lobbied EPA to replace the policy. On Jan. 3, 2007 the agency published a proposed rule to replace it, but never finalized the rule. In the time since, ACA continued to press EPA for reconsideration of the rule, to no avail.

Working through Congress

ACA repeatedly raised the “Once-in, Always-in” policy in response to EPA and the Department of Commerce Requests for Information from industry on burdensome and costly regulations, arising from the two Executive Orders. Last year, ACA underscored the policy’s unreasonableness and encumbrance on industry before the U.S. Senate’s Environment and Public Works Committee (EPW), noting that many industry facilities subject certain MACT standards were now “area source” facilities, but still had to comply with the onerous and costly requirements.

ACA’s testimony noted that the policy “is outdated and unnecessary and imposes a substantial burden on industry that well exceeds any benefits. Industry resources spent on compliance could be used instead for R&D, or modernization activities. This policy also acts as a disincentive for industry since facilities have no incentive to voluntarily reduce HAP emissions below major source thresholds.”

Following ACA’s advocacy, Sen. John Barrasso (R-WY), chair of the Senate EPW and Sen. Shelley Moore Capito (R-W.V.), chair of the EPW Subcommittee on Clean Air and Nuclear Safety, sent a letter to the EPA Administrator asking him to withdraw the “Once-in, Always-in” policy. The letter quoted ACA, and just weeks later, EPA officially rescinded the policy.

ACA is proud of spearheading this effort, and that its decade-long advocacy will help save industry millions of dollars in compliance costs.

Transparency in Regulatory Science

Building on this success, ACA pressed for further regulatory reform at EPA, urging greater openness in the science that underpins its regulations. ACA, as part of a broad collation, persuaded EPA to propose the “Strengthening Transparency in Regulatory Science” rule, published in April 2018. The proposed rule calls for EPA to provide access to underlying data from science-related studies in support of important regulatory decisions. Under the proposed rule, EPA would also be required to describe variability and evaluate default assumptions contained in scientific studies it uses in a significant regulatory action. EPA would further be required to conduct independent peer review on all pivotal regulatory science used to justify significant regulatory actions.

Notably, the proposal authorizes EPA to grant exemptions on a case-by-case basis. When it is not feasible to make dose-response data and models publicly available or peer review is not feasible, EPA exceptions would be authorized in a manner that would protect confidentiality, trade secrets, national security or otherwise, in compliance with the law.

ACA also responded to EPA’s solicitation for comments, offering suggestions for further clarification and practical enhancement. The association is hopeful that a more transparent regulatory process by which industry can openly question and challenge EPA’s scientific regulatory rationale will yield more reasonable and mitigated regulation. ACA will remain engaged in this rulemaking with industry’s interests in mind, as well as support legislation in Congress that will help facilitate a more open, thoughtful, and accountable regulatory process providing the appropriate variety of regulatory analyses.

SCIENCE & TECHNOLOGY

American Coatings SHOW & CONFERENCE

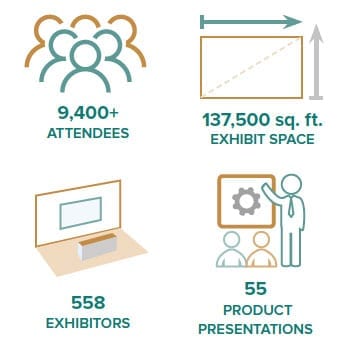

In 2018, ACA marked 10 years of showcasing the industry’s scientific and market innovations, with its fifth biennial American Coatings SHOW & CONFERENCE.

The 2018 SHOW Set Record Numbers

The Conference Boasted 10-Year Record Highs

10 PRE-CONFERENCE TUTORIALS

96 TECHNICAL PRESENTATIONS

41 POSTER PRESENTATIONS FEATURING ADVANCED RESEARCH

28 GRADUATE STUDENT PRESENTATIONS

12 ACADEMIC INSTITUTIONS REPRESENTED

The show and conference have greatly enhanced ACA’s role as a provider of science and technology information and programs to the paint and coatings industry, addressing the current and future needs of coatings industry scientists and technologists, and connecting industry suppliers with their customers.

Anticipating industry’s continued growth and a larger audience, planning is underway for the next American Coatings SHOW & CONFERENCE, which will be held March 30 – April 2, 2020, in Indianapolis, Ind. In the interim, ACA will focus on the coatings industry’s cutting-edge advancements at its 2019 CoatingsTech Conference to be held April 8 – 10, 2019 in Cleveland, Ohio. The event will convene the industry’s scientific and technological leaders to a focus on the conference theme: “Making Sustainability Ideas Happen: Coatings for the Future.”

STEM Education Initiative

In 2018, ACA rolled out its Science, Technology, Engineering and Mathematics (STEM) initiative aimed at middle school students. Working with universities and companies that have existing outreach programs, ACA assembled a presenter network that will make use of the curriculum content for middle school science teachers. The curriculum provides a window to the industry’s technical values and role in supporting society.

IN 2018, MATERIALS WERE DISTRIBUTED TO APPROXIMATELY 3,700 SCIENCE TEACHERS AT 1,005 SCHOOLS, REACHING APPROXIMATELY 211,000 STUDENTS.

The program is geared toward teacher-student engagement at a critical scientific learning point for students. The engaging curriculum features several worksheets and practical activities for students, as well as a career guide.

Journal of Coatings Technology

and Research (JCTR)

ACA’s scientific journal, the Journal of Coatings Technology and Research (JCTR), grew substantially over the past year. Full-text downloads saw a one-year jump from 93,118 to over 107,000. In addition, the Impact Factor, a widely accepted measure of a journal’s effectiveness, increased from 1.557 to 1.619 — considered to be a significant jump by scholarly publication standards.

JCTR is a respected forum for the exchange of original research, experience, knowledge, and ideas among those with a professional interest in the science, technology, and manufacture of paints, inks, and related coatings and their raw materials. Papers judged to be of high scientific and technological quality are published, subject to the requirements of rigorous peer review. Over the past two years, the number of annual submissions and the quality of the papers accepted have also risen dramatically, from 609 submitted in 2015 to 730 in 2017, with only 20 percent being accepted for publication. This high rejection rate ensures that the papers published are of the highest quality, highlighting the industry’s leading research and advancements.

Materials of Concern “Big Data” Project

In 2018, ACA’s Materials of Concern “Big Data” Project, conducted with the Center for Innovation Management Studies (CIMS) at North Carolina State University, completed the first year of a 3-year research and development plan. Efforts in 2018 centered around developing the software interface to allow access to the public data linking chemical names to health or environmental effects. The software design includes a “Scorecard,” “Heat Map,” and “Source Analysis” profiling tools to help provide actionable intelligence.

Ultimately, using sophisticated data-mining programs and interactive software, the project will create a tool for both R&D and product stewardship professionals in the industry to better assess formulation and product-use practices.

PAINTCARE®

Notable PaintCare® Statistics

Post-consumer Paint Collected

Registered Manufacturers

PaintCare-run Events

Paint-only Events

Large volume Pickups

Paint Drop-off Sites

HHW and Other Events

Program Milestones

ACA’s PaintCare — the industry-led end-of-life management program for post-consumer paint — reached new heights over the last year. The California program, PaintCare’s largest, celebrated its fifth anniversary. At the time of the anniversary, that state program alone had collected 12 million gallons of paint for stewardship, a milestone which it has since surpassed.

Meanwhile, the amount of leftover paint collected in all eight PaintCare states and the District of Columbia combined was nearly 30 million gallons this year — with the program managing over 500,000 gallons monthly. Of that total, approximately 75 percent is latex paint, and 25 percent is oil-based paint. This impressive statistic comes less than a decade since PaintCare began operations. Its first program began in Oregon in July 2010, and eight new programs were added soon thereafter, with California launching in 2012; Connecticut in 2013; Minnesota, Rhode Island, and Vermont in 2014; Colorado and Maine in 2015; and the District of Columbia in 2016.

PaintCare is an incontrovertible industry stewardship success story that underscores the coatings industry’s environmental leadership. With its growth, the program now boasts over 200 manufacturers registered and participating in the program. Across the nine program jurisdictions, it has 1,784 year-round paint drop-off sites, the large majority of which are paint retailers. These sites provide access for post-consumer paint drop-off within 15 miles of most state residents.

Securing the Program’s Future

Last year, ACA defeated a bill in the Colorado Senate that would have effectively dismantled the state’s PaintCare program. ACA opposed the measure and touted the success of the program: the Colorado PaintCare program has established more than 160 convenient, year-round locations throughout the state where residents can drop off unwanted paint. The repeal effort was ultimately voted down in the Republican-controlled Senate, where legislators voiced support for the program.

In 2018, ACA developed inroads in new states, with a long-view strategy to engage with the state legislators to increase understanding of product stewardship and become champions of PaintCare legislation. Bills to establish the paint product stewardship program were introduced in New Jersey, New Hampshire, New York, and Massachusetts. In New Jersey, the bill has historically passed the Environment Committees in both houses and is on track to do so again this year. In previous legislative sessions, the bills successfully made it through the legislature, but then-Gov. Chris Christie refused to act on it. ACA has had encouraging discussions with Gov. Phil Murphy and the New Jersey Department of Environmental Protection, and at this writing, is cautiously optimistic that the bill will be signed into law.

PaintCare legislation made significant progress in New York and Massachusetts. In New York, after several years of advocacy, the Senate and Assembly leadership finally agreed to the bill language. The bill passed the Senate (as it had in years past), but the Assembly ran into procedural obstacles. This agreement, however, positions the legislation for success in the upcoming 2019 session. And in Massachusetts, the bill passed the House Environment Committee and gained support before falling victim to legislative horse-trading. This progress, however, builds upon Senate support developed in 2017 that will help advance the bill in the next session. The effort in New Hampshire is young, and more education and outreach are necessary in the state to gain any momentum.

In 2018, significant progress was nonetheless achieved in raising awareness among decisionmakers in new states while PaintCare solidified its base of support in existing PaintCare states. Toward that end, ACA staff attended the 2018 National Conference of State Legislators expo in Los Angeles, showcasing PaintCare’s accomplishments and rapid growth with legislators from over 15 states around the nation. PaintCare and its success story were met with overwhelmingly positive reaction and encouraged state interest in the program.

SUSTAINABILITY &

GREEN BUILDING

Inaugural Sustainability Report

In 2018, ACA issued its first Sustainability Report highlighting industry stewardship programs, member sustainability initiatives, and industry’s widespread VOC reductions and minimized environmental footprint.

The report follows three pillars of Sustainability:

It tells the industry story of the industry as a responsible contributor to the nation’s economy and infrastructure; of products that protect and preserve valued objects; of businesses that provide thousands of jobs and of giving back to our communities; of science and technological innovators invested in the environmental well-being and advancement of our world.

Preservatives Life-Cycle Assessment

Last year, ACA spearheaded a study to assess the environmental performance of five different architectural coating preservation scenarios using a Cradle-to-Grave Life-Cycle Assessment (LCA), given that the use of preservatives in paints and coatings, among other construction products, has come under increased scrutiny. Preservatives play a crucial role in enhancing shelf-life, ensuring the product does not spoil before being used, and protecting the dried coating film from biologic growth. The primary goals of the LCA were to determine the environmental impacts and benefits that wet-state and dry-film preservatives play in architectural coating systems, and to see how reducing, eliminating, or replacing certain preservatives impacted the coating’s overall sustainability profile.

THE STUDY FOUND THAT, RELATIVE TO THE BASELINE SCENARIO, CHANGING THE PRESERVATION STRATEGY INCREASED THE ENVIRONMENTAL BURDEN OF THE SYSTEM RANGING FROM A 50 PERCENT HIGHER IMPACT TO ALMOST A 400 PERCENT HIGHER IMPACT, DEPENDING ON THE SPECIFIC SCENARIO.

The LCA models also showcased that the preservatives themselves were typically responsible for <1 percent of the total impact in each impact category (Global Warming Potential, Acidification, Eutrophication, Ozone Depletion, and Smog Formation).

The ACA Sustainability Committee’s Preservation Product Stewardship Working Group published the LCA study, which found increased environmental impacts from use of alternatives to traditional preservatives. This important study should help ACA advocate for the critical importance of preservatives in coating formulations.

Green Building Standards & PCRs

In 2018, ACA’s Sustainability Committee continued to address the development of various green building standards and codes that contain environmental, health, indoor air quality, and chemical requirements for building materials that affect the architectural coatings, adhesives, and sealants market.

Notably, at a hearing of the International Code Council, ACA testified in opposition to a proposal that sought to require site-applied or installed adhesives and sealants on the interior side of the building envelope to comply with strict California South Coast Air Quality Management District (SCAQMD) VOC limits. The proposal was defeated at the hearing due, in part, to ACA’s testimony.

Separately, ACA initiated Product Category Rules (PCRs) for Resinous Floor Coatings (now under external review) and Powder Coatings. ACA engaged a third-party developer of public health standards and certification programs to develop the PCRs, following membership’s embrace of the PCR for Architectural Coatings ACA facilitated in 2015.

The utility of PCRs is timely and considerable, since decisionmakers are increasingly considering information about the life-cycle impacts of products when selecting which products they choose to sell, specify, or use. Retailers, standard-setting bodies, and consumers are requiring information or giving favorable status to products and brands able to describe their life-cycle impacts and benefits. A PCR provides an agreed-upon framework for measuring the environmental impacts of a product based on a defined set of criteria. This allows manufacturers to conduct LCAs of their products in a standardized way, and publish this information in an Environmental Product Declaration, if they so choose.

Recognizing the need to respond to this market demand, ACA is facilitating development of the new PCRs to position the industry to compete with other building materials that already have PCRs.

2018 ACCOMPLISHMENTS

In addition to the areas of focus above, the association achieved success with other industry related endeavors in 2018.

Clean Air & Environment

• ACA convinced the State of Washington to delay implementation of its planned ban on copper biocides for marine coatings. ACA also commented on an “alternatives report” the state commissioned to study the feasibility of such a ban.

• ACA persuaded California’s SCAQMD to make several revisions to its Final Amended Rule 1168, including reinstating the exemption for aerosol adhesives and primers; extending the compliance date for various adhesive and sealant categories that will have new, lower VOC limits; changing the reporting requirements to a less rigorous schedule with a sunset date; and adding a provision that requires SCAQMD to develop a guidance document that will clarify which product types are tested by methods specified under the rule.

• ACA, in coordination with its Ohio Paint Council and the Ohio Manufacturers’ Association, persuaded Ohio EPA to make important revisions to its Universal Waste regulation, which now designates hazardous non-empty aerosol containers and hazardous paint and paint-related waste as universal waste. Among the revisions ACA secured in the final rule: modifications to the definitions of “aerosol container” and “paint;” changes to the methods for puncturing, shredding, or crushing containers; and the addition of other methods for capturing VOCs from aerosol containers.

• ACA convinced the California Air Resources Board (CARB) not to include more stringent colorant and stain limits in the proposed new Architectural and Industrial Maintenance (AIM) Suggested Control Measure (SCM) the board is developing. ACA also convinced California’s Ventura County Air Quality Management District to postpone adopting a proposed rule that would have included the stringent SCAQMD limits, and to instead wait for CARB to complete its SCM.

• ACA comments compelled the Ozone Transport Commission (OTC) to maintain consistency between its updated Model Rule for Consumer Products and CARB’s 2015 Consumer Products Rule. ACA also persuaded OTC to postpone developing a new “Phase III” model AIM rule until CARB’s SCM is completed.

• ACA convinced SCAQMD to postpone adoption of Rule 120, Credible Evidence. The objective of Rule 120 is to clarify that SCAQMD could establish violations by any credible evidence, beyond for example, test data by an applicable approved test method. Rule 120 would have greatly expanded the type of information that SCAQMD compliance staff could use to issue a Notice of Violation, including product labeling, marketing and/or website information.

• ACA convinced SCAQMD to postpone adoption of Rule 120, Credible Evidence. The objective of Rule 120 is to clarify that SCAQMD could establish violations by any credible evidence, beyond for example, test data by an applicable approved test method. Rule 120 would have greatly expanded the type of information that SCAQMD compliance staff could use to issue a Notice of Violation, including product labeling, marketing and/or website information.

• ACA secured exemptions for coatings, ink, adhesive, and resin manufacturing operations from the industrial cleaning solvent requirements in rulemakings in Massachusetts, Maine, New Jersey, Pennsylvania, and New York.

Federal Advocacy

• ACA lobbied Congress to reauthorize the Chemical Facility Anti-Terrorism Standards (CFATS) program scheduled to sunset in January 2019, and published a comprehensive Issue Backgrounder on the critical continuity of CFATS for industry. It also detailed several potential improvements to the program, including greater transparency for tiering determinations, risk-based personnel surety requirements, and regular review of the “Chemicals of Interest” list. Sen. Ron Johnson (R-WI) introduced a reauthorization bill on Sept. 4, which directly addresses two of ACA’s suggested improvements. At this writing, Congress was expected to reauthorize CFATs for an additional five years with some of ACA’s recommendations.

• ACA, working through a broad-based coalition, gained the introduction of the Accurate Labels Act in Congress. The legislation would establish nationwide science-based standards for government labeling programs, creating science-based criteria for all state and local labeling requirements that exceed current federal standards; allowing state-mandated product information to be provided through smartphone-enabled “smart labels” and on websites; and ensuring that covered product information is risk-based.

• ACA and other business groups pressed for comprehensive tax reform, resulting in the enactment of the Tax Cuts and Jobs Act, which included the major elements of reform ACA had urged : a lower Corporate Tax Rate of 21 percent; equitable treatment of small businesses filing under Subchapter S of the tax code in areas such as expensing of certain investments; a permanent R&D tax credit; and a robust Capital Cost-Recovery System.

Fees on Industry

• ACA worked diligently alongside member companies to educate California lawmakers about the impact on the industry of a tax on paint to fund lead paint abatement activities. In addition, ACA provided significant information on the historical efforts of the industry to address lead in paint. This legislation did not advance out of the California Assembly.

Chemicals Management

• In Vermont, ACA successfully worked with a coalition of industries to defeat a chemicals management proposal that would have imposed significant burdens on manufacturers, distributors and retailers.

• ACA filed multiple intervenors’ briefs in Environmental Defense Fund vs. U.S. EPA (D.C. Circ. Ct. of Appeals, filed Sept. 1, 2017), in support of the agency. EDF is challenging EPA’s promulgation of the Inventory Reset Rule under the amended Toxic Substances Control Act (TSCA), which was finalized on Aug. 11, 2017. In its lawsuit against the agency, EDF challenges EPA’s protections for confidential business information (CBI) in the revised TSCA inventory. ACA’s briefs buoy EPA’s arguments against EDF’s challenges to EPA’s interpretations for substantiation of CBI.

• ACA efforts on EPA’s reset of the TSCA inventory and new chemicals review resulted in the agency implementing a system to make more information available online during the new chemical review process, including status updates during review, scope of review and final determinations.

• ACA comments on EPA’s draft scope of review for the first 10 chemical risk evaluations under revised TSCA contributed to the agency focusing its efforts on risk evaluations for exposures that have the greatest potential for harm to human health and the environment. Because of ACA’s comments, EPA is excluding incidental manufacture of chemicals and other sources of de minimis exposures from the scope of risk evaluations of certain chemicals used to manufacture paints, coatings, sealants and adhesives.

• Because of ACA’s engagement, a bill in Maryland banning N-methylpyrrolidone (NMP) and Methylene Chloride in paint strippers did not advance out of committee. In California, the Department of Toxic Substances Control has delayed a decision to require alternative assessments and possible phase-out of methylene chloride in paint-stripping products, in part due to ACA’s advocacy efforts.

Trade Policy

• ACA, along with other interested groups, supported passage of the Miscellaneous Tariff Bill to eliminate taxes on products not made or available in this country. ACA’s efforts helped drive Congress to pass the bill in the summer, which President Trump signed into law in September 2018. The law encompasses more than 1,600 products, and contains several chemicals of interest to coatings manufacturers, including industrial grade nitrocellulose and heat-curable epoxy resin mixture.

• ACA repeatedly made its voice heard and encouraged a “do-no-harm” approach to U.S. renegotiation of the North American Free Trade Agreement (NAFTA), noting the immense benefits the trade agreement has borne the U.S. coatings industry over the last two decades: the U.S. coatings manufacturing base exports a significant portion of its production to Mexico and Canada — some $1.5 billion — accounting for two-thirds of the industry’s exports. ACA specifically urged the Administration to ensure that the trade agreement included both Mexico and Canada.

• ACA published updated industry statistics on employment, payroll, wages, exports, and establishments, made available on the ACA website, and featured prominently in an Issue Backgrounder sent to members of Congress. The statistics and Issue Backgrounder tell the story of the paint and coatings industry’s major contributions to the U.S economy and workforce

At this writing, all parties were on board for an amended trade agreement that should continue to benefit industry.

• Over the last year, ACA continually voiced its concern to the Office of the U.S. Trade Representative (USTR) over imposition of an ad valorem duty of 25 percent on products from China. In testimony and comments, ACA proffered industry’s position that the significant tariff increases proposed by the USTR will almost certainly impose costs on the U.S. coatings industry that will not only harm consumers and end users – including downstream U.S.-based manufacturing customers – but will also damage the currently strong competitive position of the U.S. paint and coatings industry internationally.

CoatingsVoice TM

• In 2018, ACA launched its new COATINGSVOICETM program. This grassroots initiative provides an effective way for members to get involved in the most critical legislative issues that impact the coatings industry at the local, state, and federal level, and connect directly with their elected representatives. ACA activated alerts for members to reach their federal and state representatives with campaigns to support the Miscellaneous Tariff Bill; the Accurate Labeling Act; PaintCare bills in Massachusetts and New Jersey; and repeal of the spray paint ban in Chicago.

Graffiti Resource Council (GRC)

• GRC continued its advocacy effort to rescind Chicago’s ban on the sale of spray paint within city limits, meeting with several aldermen to highlight the negative impact this 26-year-old law has had on their wards and educate them on GRC’s Model Anti-Graffiti Ordinance. GRC’s advocacy resulted in the introduction of a proposal that reforms the ban by offering an alternative approach: Responsible Retailing. Responsible Retailing maintains the existing ban on the sale of spray paint to minors under the age of 18, while also requiring signage and line-of-sight surveillance rules. This approach would allow retail stores and other small businesses in Chicago to resume selling spray paint.

International Affairs

• ACA worked with the U.S. Department of Commerce’s International Trade Administration to raise the issue that the potential classification of titanium dioxide as a Category 2 Carcinogen, or a substance suspected of causing cancer by inhalation by the European chemicals agency was a technical barrier to trade. The U.S. agency’s additional voice in this debate assisted the International Paint and Printing Ink Council (IPPIC) and ACA’s European partners as they engaged directly. Because of these efforts, a new proposal has emerged that recognizes that titanium dioxide bound in a liquid mixture does not present the same hazard.

• ACA worked with IPPIC on biofouling management efforts to provide expertise to the International Maritime Organization (IMO) on this issue, along with joining with the IMO and the UN Development Program to become a strategic partner of the new GloFouling initiative. The GloFouling project is intended to support more effective biofouling management globally. ACA and IPPIC sponsored a special session on biofouling at the World Ocean Council Sustainable Oceans Summit, attended by key leaders in the global maritime business community.

• In 2018, IPPIC continued its commitment to addressing child labor concerns in the mica supply chain by working as a board member of Responsible Mica Initiative (RMI). IPPIC also established a work group to engage in specific RMI activities to advance effective policy, including development of: procurement specifications; community development programs; a legal framework to ensure RMI activities conform to other UN labor practices; and effective communications to establish consistent messaging. IPPIC is coordinating its efforts with paint manufacturers that have also become members of RMI to establish a “Paint Industry Platform.”

• IPPIC developed a position paper to help frame the issue of microplastics in the aquatic environment, which is gaining traction, particularly in Europe. IPPIC’s paper will help decide on common definitions and allow IPPIC to engage national governments and research organizations to present data related to paint’s unlikely contribution to sources of marine pollution, i.e., microbead use, polymer/film degradation from weathering and surface preparation, and post-application clean-up among other sources.

• ACA, through the Interested Parties for Hazardous Materials Transportation coalition, submitted a letter to the U.S. Department of Transportation Secretary Elaine Chao, urging her to restore the agency’s Pipeline and Hazardous Materials Safety Administration (PHMSA) as the lead U.S. representative on the Dangerous Goods Panel (DGP) of the International Civil Aviation Organization (ICAO). PHMSA’s multimodal regulatory authority gives it the necessary scope of understanding to ensure the development of domestic and international regulations. Because of this advocacy effort, Secretary Chao restored PHMSA as the lead agency of the U.S. delegation on the ICAO DGP, which will ensure the seamless and safe transportation of goods via air mode.

• ACA contributed to the development of a paper submitted by IPPIC during the 53rd session of the UN Subcommittee of Experts on the Transport of Dangerous Goods. The paper seeks to clarify and provide relief for the requirement to supplement shipments of environmentally hazardous goods with technical chemical names. This effort resulted in a working document for the 54th session that will resolve this long-

standing issue.

Regulatory Guidance

• ACA developed guidance for members when making environmental claims relating to low- or zero-VOC emission in accordance with the regulatory and enforcement landscape at FTC. FTC’s series of final consent orders in 2013 and 2018, along with the Green Guides and Endorsement Guides, provide a template to substantiate health and environmental claims based on emissions, rather than actual VOC content as previously allowed.

• In 2018, ACA hosted 23 webinars for members on topical regulatory issues, with nearly 1,000 members participating in the webinars on a range of domestic and global issues, including Green Building standards, California’s SCM development, and titanium dioxide classification in Europe.

• ACA developed regulatory matrices covering exempt compounds for multi-state and air district regulations, and VOC limits for industrial surface coating and automotive refinish regulations. ACA also developed an interactive map for consumer product VOC limits at the national, state, and regional level.

Awards

• PaintCare’s Connecticut, Maine, Rhode Island, and Vermont programs received the Northeast Recycling Council’s 2018 Environmental Sustainability Leadership Award for their exemplary record of sustainable materials management in the region.

• ACA’s trade magazine, CoatingsTech, was honored with a 2018 Association Media and Publishing EXCEL Bronze Award in the “Best Single-Issue Topic” category, recognizing the special issue on automotive coatings.

• ACA was recognized by the National Association of Manufacturers’ (NAM) Council of Manufacturing Associations as one of the 10 best manufacturing associations for which to work. ACA believes the award is recognition for the dynamic paint and coatings industry it represents.